Innovative Technology Designs Start with the Right PCB

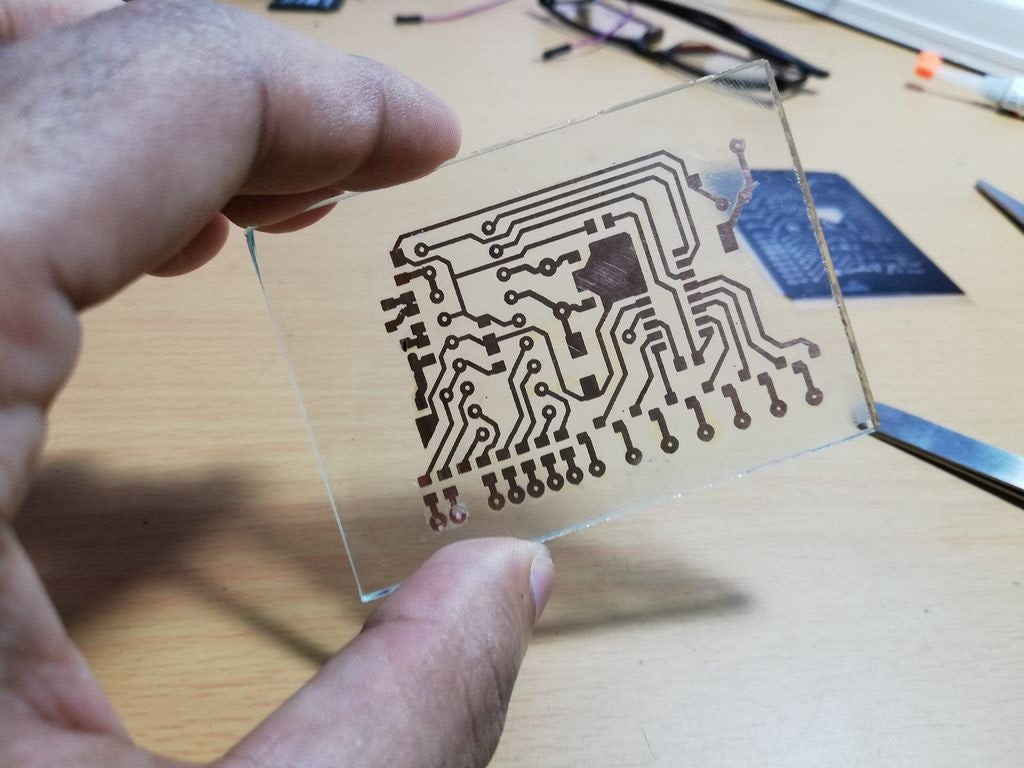

The R&D work of the DEEE is facilitated by a state of the art printed circuit board (PCB) fabrication laboratory. It is a facility dedicated to the design and fabrication of printed circuit boards. It is equipped with a variety of software and hardware resources, including CAD software, 3D printers, and milling machines. The laboratory is used by students and faculty in the electrical and electronic engineering department to design and prototype new electronic devices.

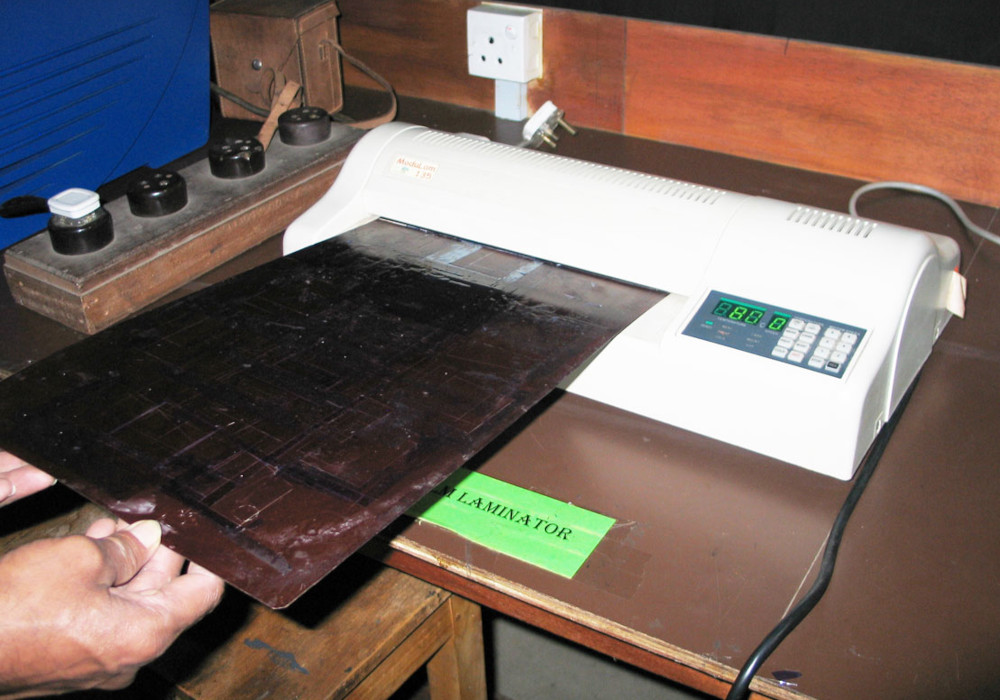

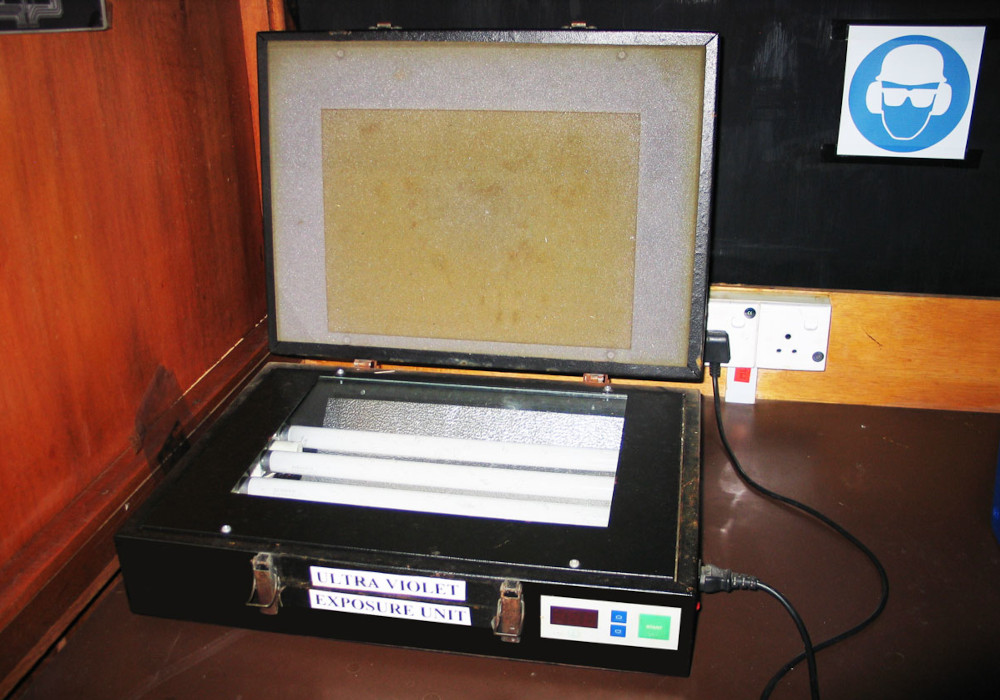

The laboratory is also equipped to handle not only standard FR-4 based PCBs but advance PCBs such as multi-layer boards up to 8 layers, RF and microwave board requiring high precision, and flexible PCBs. The key fabrication techniques used include precision CNC milling and photolithography. The laboratory is also equipped with a pick and place machine, soldering stations for hand soldering, and a re-flow over with programmable temperature profiling.

EQUIPMENT AND EXPERIMENTAL SETUPS

Below, you will find pictures of laboratory setups, equipment, etc., belonging to the PCB Fabrication laboratory.

| CNC MILLING MACHINE and PHOTO-LITHOGRAPHY | |||

| PCB Milling Machine | Photo-Plotter | Multi-layer Press | PCB Laminating Machine |

|

|

|

|

| UV Exposure Unit | Spray Developer/Etcher | Cupric Chloride Bubble Etcher | Gold, Copper, Tin Platting Bath |

|

|

||

| CIRCUIT ASSEMBLY AND SOLDERING | |||

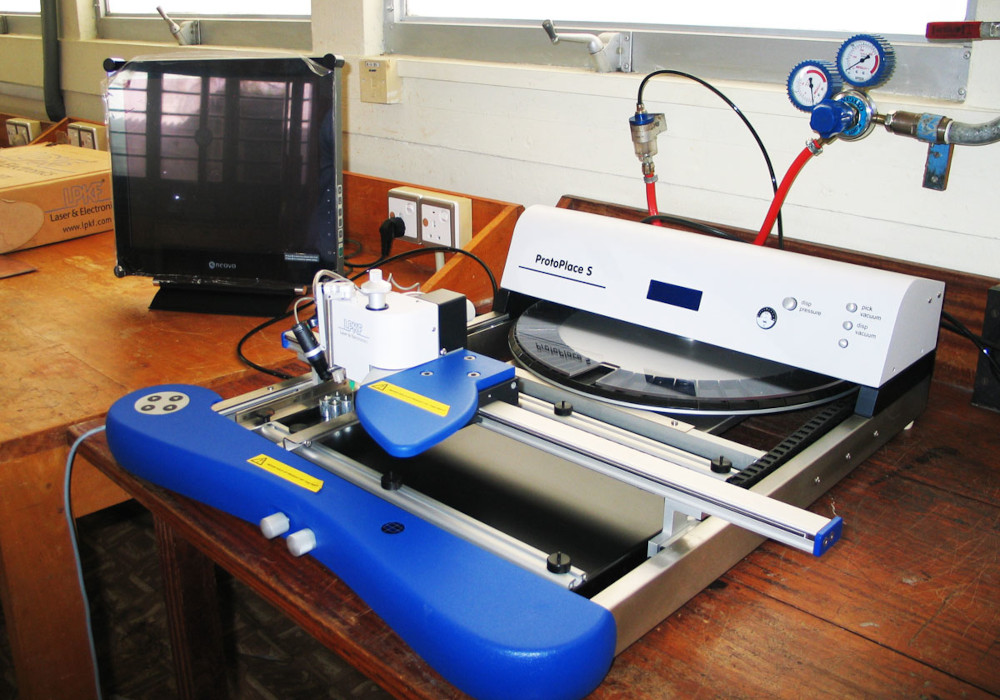

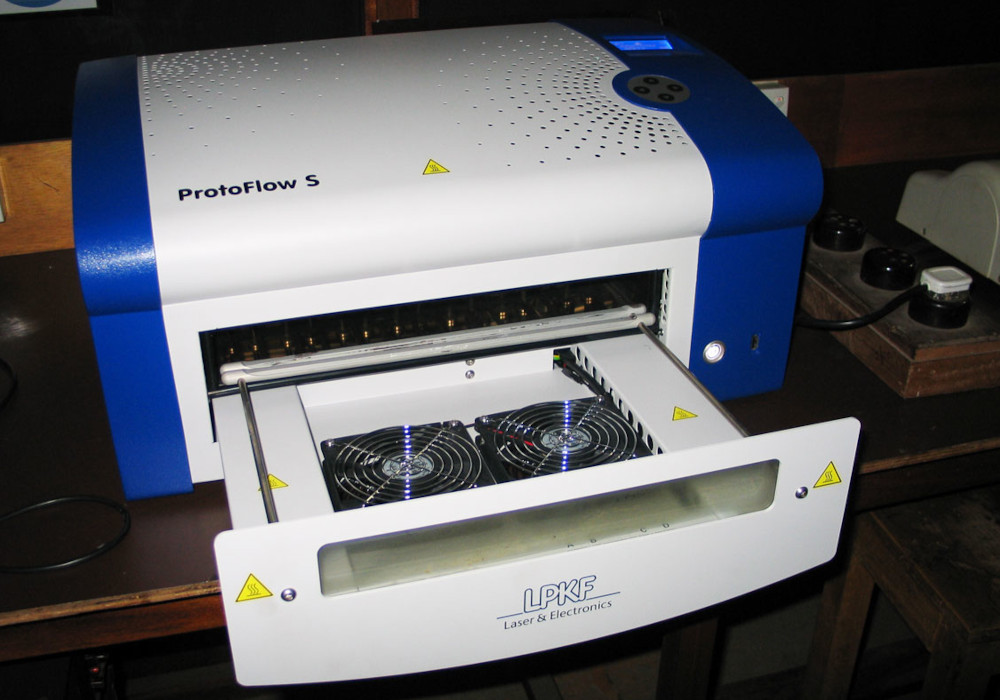

| LPKF Pick and Place Machine | Reflow Oven | ||

|

This machine is semi-automatic and is capable of placing surface mount components which require high accuracy such as 0.25 mm pitch ICs and ball-grid array ICs. |

|

LPKF ProtoFlow-S. This machine is temperature profile programmable and is used for soldering and other curing processes that require accurate temperature profiling. |

| Soldering de-soldering Stations | |||

|

The laboratory is equipped with both find tip solder stations and hot-air stations for both SMT and through-hole type soldering/de-soldering.

|

|

|

| FABRICATION AND ELECTROPLATTING | |||

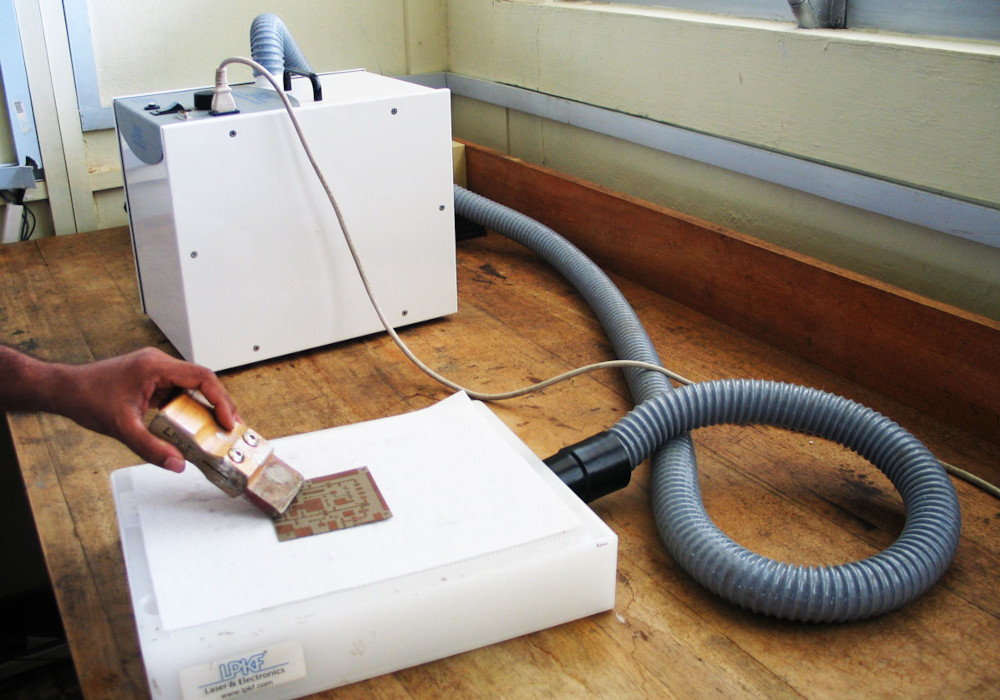

| LPKF Pro-Conduct through hole Fabrication Unit | Copper Electroplating | ||

|

This is based on an hole-wall activator solution and traditional copper electroplating. |

||